- ▶Track Rebuilding

- ・Shoe Bolt Torque Controller

- ・Track Shoe Rebuilding Machine

- ・Track Link Welder

- ・Track Press 230/330

- ▶Roller and Idler Rebuilding

- ・Roller & Idler Press

- ・Roller And Idler Rebuilding Machine

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Service Car

- ・Lubrication Truck

Workshop Equipment and Tools

Undercarriage Rebuilding

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

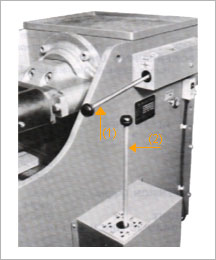

- (Single lever control)(1) Indexer lever (2) Ram lever

- (Indexer)(1)Adjusting nut (2) Adjusting nut (3) Adjusting rod

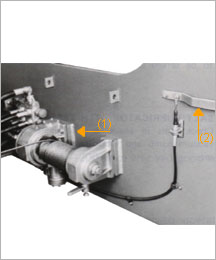

- 1)Winch (2) Winch lever

TRACK PRESS MTP-330

-

The MTP-330 Track Press can disassemble and assemble the track links of even the largest bulldozers in operation. Now turning the pins and bushes or completely replacing the link components, of even the largest tractors in the field, is much easier and faster with this larger capacity track press.

1) Larger Capacity

2) Precise Disassembling and Assembling

3) Safer Operation

4) Higher Efficiency

5) Ease in Handling

FEATURES

1. This press has a zero deflection frame at a full 330 tons of pressure on both rams. The unique design of the machine consists of a massive cross section frame and a tension bar. This design forms the basis for the strongest, most rigid press frame available.

2. A sliding door separates the work area preventing injury from shattered metal which can occur at 330 tons of pressing force. A shatterproof window provides a clear view of the entire operation. The door has wide frontal openings for ease of tool changing and ball bearing suspension for smooth, easy operation.

3. The cylinder mounts, tool bars and the jaw are located on precisely machined surfaces for unsurpassed accuracy. Each the tool head is carried on lubricated brass slide bearings to assure tolerance in tooling alignment.

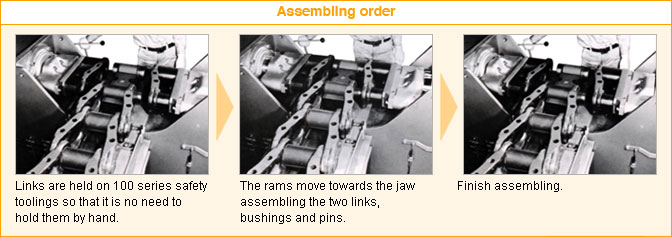

4. This press has a longer ram stroke and it allows the use of 100 Series Safety Toolings. There is no longer any need of holding the track link in position by hand while assembling with 100 Series Toolings. It safer, with faster and more efficient operation.

5. On the MTP-330, a single lever performs both the raising and lowering of the table and the forward and backward indexing of the track links.

Further, an adjusting rod and nut are provided for fixing the proper indexing pitch according to the track of tractor model. This makes the track press operation easier and much faster.

Also, presetting a 1/2 pitch backward and forward is available, which is required for assembling the links of some specific tractor models.

6.The winch control lever is located very close to the winch to facilitate operator’s job.

SPECIFICATIONS

OPTIONAL ATTACHMENTS FOR TRACK PRESS

-

GRAVITY CONVEYERS AND CHUTE

4 ~ 5 conveyers and stands and 1 chute.

TOOLINGS

Toolings are made from the finest quality steel and special heat treatment is given to assure long life. The new adjustable pitch jaws and multi pitch tool bars are considered a major break-through in design and application in track press tooling. The interchangeability of tooling between makes and models of tractors results in a substantial cost saving and a reduction of tool inventory. Complete tooling is available for a wide range of tractor makes and models.

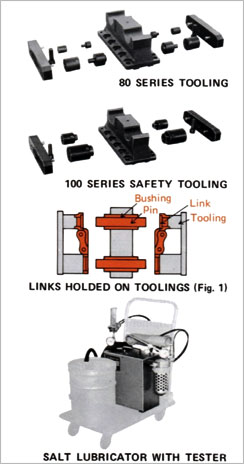

Now, 2 kinds of toolings are available from us.

One is conventional type 80 series tooling and the other is newly developed 100 series tooling on which links are holded as shown in Fig. 1.

That is why it is no need to hold them by hand.

You are requested to specify both the tractor models to be served and the kind of tooling when ordering. SALT LUBRICATOR WITH TESTER Check seals in sealed and lubricated track link by vacuum pump and lubricate pin and bush Eall in one set.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact