- ・General Service Equipment and Tools Catalog

- ・Crawler Tractor Service Tools

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Lubrication Truck

Workshop Equipment and Tools

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

- Master Pin Remover & Installer

- shown with electro hydraulic pump

- Sprocket Remover & Installer

- shown with hand operated pump

- These Service Tools are designed and manufactured by Maruma Technica, which is the leading company in the field of maintenance for construction machines in Japan. Based on the wealth of experience in this field, these products are manufactured taking the following points into consideration.

- 1) The products are rigid enough to withstand heavy operations.

- 2) The products are as light as possible, in order to be suitable for easy handling.

- 3) The products are adaptable for every kind of tractors such as Komatsu, Caterpillar, etc.

- 4) The spare parts are designed to be interchangeable throughout the world.

- 5) Each product has the characteristic attachment for a wide range of operations.

- We can supply other special tools that are adaptable to Maruma Service Tools. And every kind of inspecting, repairing and maintenance equipment for earthmoving machines are also available.

- [N.B.] The contents of this catalog are subject to change without notice.

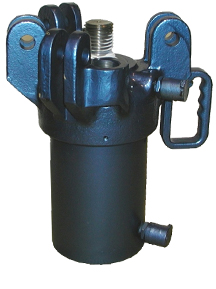

- Portable service tool consists of hand operated and electro hydraulic pumps, large and small cylinders and pullers that can easily be transported. Our pumps are the most convenient, lightest and smallest pumps in the world and are extensively utilized for a wide range of purpose. Especially in the field of maintenance for construction equipment, every kind of assembling and disassembling can be performed safely and effectively in combination with the special tools such as master pin remover& installer or sprocket remover & installer.

- Code No.CY-0101

- Ref. No.910-0001-001

- ModelMT-700P

- Max. working pressure MPa (kgf/cm2)68.6 (700)

- Low working pressure

MPa (kgf/cm2)4.1 (25) - Oil capacity liters5

- Recommend oilSAE 10

- Control valve type3 position 4 way

- Dimensions (L x W x H) mm1076 x 207 x 304

- Mass kg31

- 1. In combination with several cylinders (100 ton 70 ton), pullers (150 ton 50 ton 30 ton) etc., this hydraulic pump is used for a wide range of operations.This is the most fundamental tool for the construction machinery maintenance.

- 2. This pump is designed to be easily transported by separating the attachment from the pump. Thus, it is most suitable for field services, as compared with conventional presses.

- 3. As four kinds of scales are notched in one gauge, the operating tonne of each cylinder and puller can be measured and the exact operations based on the specified pressures can be performed.

- 4. The sequence valve is installed in the pump, which controls the movement of the ram. When the load is light, 129cc oil per stroke is delivered by the action of the low pressure piston and the ram moves fast, and when the load becomes heavier, the oil pressure exceeds 25 kg/cm2 and high pressure pump operates automatically and 4.6cc oil per stroke is delivered and the operation of the handle becomes lighter.

- 5. By changing the lever of the four-way valve both actions of pushing and pulling of the cylinder ram can be achieved.

- 6. As the special automatic sealing coupler is used for removing the cylinders and pullers from the pump, the flow out of high pressure oil can be eliminated.

- 1. Cylinder, ram and piston are made of special steel and the weight is relatively very light.

- 2. Both operations for pushing and pulling can be performed.

- 3. These cylinders are used with electric or hand-operated pump (MT-800PE, 800PEC or 700P) for removing and installing the track master pin and sprocket.

- 980 kN (100 Ton) Cylinder

- The MT-100CL cylinder has a longer stroke than the MT-100C, allowing the operation to be accomplished in one stroke.

- Code No.CY-0306CY-0301

- Ref. No.910-0134-000910-1105-000

- ModelMT-100CLMT-100C

- Max. working pressure MPa (kgf/cm2)68.6 (700)68.6 (700)

- Capacity ram out kN980980

- Capacity ram in kN833833

- Ram travel mm356152

- Dimensions (L x W x H) mm315 x 265 x 597315 x 265 x 393

- Mass kg7350

- 686 kN (70 Ton) Cylinder

- The MT-70CL cylinder has a longer stroke than the MT-70C, allowing the operation to be accomplished in one stroke.

- Code No.CY-0305CY-0302

- Ref. No.910-0135-000910-1116-000

- ModelMT-70CLMT-70C

- Max. working pressure MPa (kgf/cm2)68.6 (700)68.6 (700)

- Capacity ram out kN980686

- Capacity ram in kN833490

- Ram travel mm180152

- Dimensions (L x W x H) mm254 x 252 x 382254 x 252 x 353

- Mass kg33.531

- 1. The operation for pulling direction can be achieved by utilizing the center hole as well as the operation for pushing direction. (All pullers)

- 2. By screwing in the attachments using outer or inner thread, these pullers can be applied in the narrow space. (MT-50CC, MT-30CA)

- 3. The range of usage can be widened by adopting the spacers on the ram.

- 4. These pullers are used with electric or hand operated pump. (MT-800PE, 800PEC or 700P)

- Code NoCY-0405

- Ref. No.910-0132-000

- ModelMT-150CS

- Max.woking pressure

MPa (kg/cm2)68.6 (700) - Capacity kN1470

- Ram travel mm127

- Dia.of center hole mm65

- Dimensions mmϕ218 x 83

- Mass kg54

- Code NoCY-0401

- Ref. No.910-0123-000

- ModelMT-50C

- CATNo5P2998

- Max.woking pressure

MPa (kg/cm2)68.6 (700) - Capacity kN490

- Ram travel mm50

- Dia.of center hole mm33.3

- Dimensions mmϕ139 x 129

- Mass kg14

- Code NoCY-0402

- Ref. No.910-0121-000

- ModelMT-50CC

- Max.woking pressure

MPa (kg/cm2)68.6 (700) - Capacity kN490

- Ram travel mm13.8

- Cylinder thread inch5 - 7/16" x 14

- Dia.of center hole mm36

- Dimensions mmϕ139x 90

- Mass kg10

- Code NoCY-0403

- Ref. No.910-0118-000

- ModelMT-30C

- Max.woking pressure

MPa (kg/cm2)68.6 (700) - Capacity kN294

- Ram travel mm53.3

- Dia.of center hole mm27

- Dimensions mmϕ105 x 122

- Mass kg6.3

- Code NoCY-0404

- Ref. No.910-0122-100

- ModelMT-30CA

- Max.woking pressure

MPa (kg/cm2)68.6 (700) - Capacity kN294

- Ram travel mm13.8

- Outer thred mmM115 x 2.0

- Dia.of center hole mmM33 x 2.0

- Dimensions mmϕ119 x 90

- Mass kg7

CRAWLER TRACTOR SERVICE TOOLS

SPECIAL FEATURES

ADDITIONALY

INTRODUCTION

1-A HAND OPERATED PUMP

with Three position, Four Way Valve, Pressure Gauge with working tonnage display and Two High Pressure Hoses with coupling.

with Three position, Four Way Valve, Pressure Gauge with working tonnage display and Two High Pressure Hoses with coupling.

1-B ELECTRO-HYDRAULIC PUMP

with Three position Four, Way Valve, (Pressure Gauge with working tonnage display and Two High Pressure Hoses with coupling are optional)

These pumps are powered by an electric motor to provide the same functions and much faster operation than the hand operated MT-700P. The Electro-Hydraulic Pumps are now available for use with all hydraulic cylinders and pullers for disassembling and assembling the undercarriage of tractors and other construction equipment.

1-C CYLINDER

with Three position Four, Way Valve, (Pressure Gauge with working tonnage display and Two High Pressure Hoses with coupling are optional)

These pumps are powered by an electric motor to provide the same functions and much faster operation than the hand operated MT-700P. The Electro-Hydraulic Pumps are now available for use with all hydraulic cylinders and pullers for disassembling and assembling the undercarriage of tractors and other construction equipment.

1-C CYLINDER

1-D PULLER

These Center-Hole rams offer you complete flexibility. Forcing screws, cables or rods can be extended right through the piston’s center hole, permitting hundreds of applications.

1470 kN (150 Ton) Puller

This puller is for final drive disassembling and assembling operations on large tractors. However, it can also be used in other applications.

This puller is for final drive disassembling and assembling operations on large tractors. However, it can also be used in other applications.

490 kN (50 Ton) Puller

490 kN Puller This puller is used for removing and installing of steering clutch of large tractors. However, it can also be used in other applications.

490 kN Puller This puller is used for removing and installing of steering clutch of large tractors. However, it can also be used in other applications.

490 kN (50 Ton) Puller Short stroke

This puller is used for removing and installing of steering clutch of large tractors. However, it can also be used in other applications.

This puller is used for removing and installing of steering clutch of large tractors. However, it can also be used in other applications.

294 kN (30 Ton) Puller

294 kN Puller This puller is used for removing and installing of steering clutch of small tractors. However, it can also be used in other applications.

294 kN Puller This puller is used for removing and installing of steering clutch of small tractors. However, it can also be used in other applications.

294 kN (30 Ton) Puller Short stroke

294 kN Puller This puller is used for removing and installing of steering clutch of small tractors. However, it can also be used in other applications.

294 kN Puller This puller is used for removing and installing of steering clutch of small tractors. However, it can also be used in other applications.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact