- ▶Track Rebuilding

- ・Shoe Bolt Torque Controller

- ・Track Shoe Rebuilding Machine

- ・Track Link Welder

- ・Track Press 230 /330

- ▶Roller and Idler Rebuilding

- ・Roller & Idler Press

- ・Roller And Idler Rebuilding Machine

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Service Car

- ・Lubrication Truck

Workshop Equipment and Tools

Undercarriage Rebuilding

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

- he MTP-230 Track Press is the ideal machine for disassembling and assembling the track links of small to medium size bulldozers and excavators. It is efficient and easy to operate, which decreases the time required to turn the pins and bushes, or to completely replace the track link parts. This is one of the main machines of the undercarriage repair workshop.

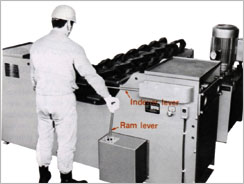

- (Single lever control) (1) Indexer lever (2) Ram lever

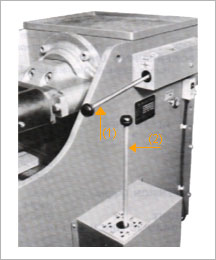

- (Indexer) (1)Adjusting nut (2) Adjusting nut (3) Adjusting rod

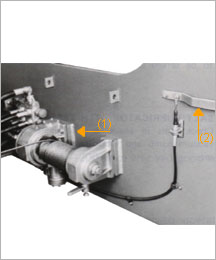

- 1)Winch (2) Winch lever

- RAMCAPACITY230 short ton/cylinder

- TRAVEL180 mm (7.08 E

- SPEED (theoretical)50 Hz60 Hz

- Approach2150 mm (84.6 E/min.2580 mm (101.6 E/min.

- Pressing418 mm (16.5 E/min.502 mm (19.7 E/min.

- Return4500 mm (177.2 E/min.5400 mm (212.6 E/min.

- JAWFixed pitch jaw are prepared.

- POWER SUPPLY UNITPumps (Positive Displacement Type)50 Hz60 Hz

- High pressure 58.8 Mpa (600 kg/cm2)(8535 psi)14.48 mm/min.17.37 mm/min.

- Low pressure 9.8 Mpa (100 kg/cm2)(1422 psi)60.0 mm/min.72.0 mm/min.

- RESERVOIR 190 liters

- MOTOR11kW, 3 phase 220V 50/60Hz Electric high torque motor

- (as same as 19 kW of conventional motor)

- (Various voltages are available upon request)

- Drip-proof with cover

- Standard Voltage

- DIMENSION (Approx.)Width 2370 mm (93.9 E Height 1270 mm (50 E Length 2845 (112 E (W/indexer)

- WEIGHT3750 kg (8335-lbs)

- HYDRAULIC WINCHpulls track up on to the gravity conveyers and on to the track indexer 3,500 kg pull (short ton).

TRACK PRESS MTP-230

FEATURES

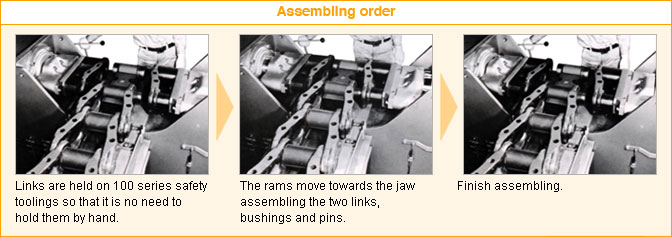

Track link assembling with 100 series safety

tooling.

Track link assembling with 100 series safety

tooling.

2. The fixed jaw table on the MTP-230 is of a rugged one-piece cast steel structure, resulting in remarkably long durability.

3. A single lever can control �E�in and out motion�E�Eof the rams not only on either side respectively but also on both sides simultaneously. This helps operator speed up assembling to a great extent.

4. This press has a longer ram stroke and it allows the use of 100 series safety toolings.

It is no longer necessary to hold the link by hand while assembling with 100 series toolings. It provides the equipment with more safety and more working efficiency.

5. A single lever controls both the raising and lowering of the table and the indexing of the link.

5. A single lever controls both the raising and lowering of the table and the indexing of the link.Further, an adjusting rod and nut are provided for fixing the proper indexing pitch according to the link of tractor models.

This makes the track press operation easier and much faster.

6. The winch control lever is now located very close to the winch to facilitate operator’s job though it was located near the main equipment operating levers.

SPECIFICATIONS

OPTIONAL ATTACHMENTS FOR TRACK PRESS

-

GRAVITY CONVEYERS AND CHUTE

4 ~ 5 conveyers and stands and 1 chute.

TOOLINGS

Toolings are made from the finest quality steel and special heat treatment is given to assure long life. The new adjustable pitch jaws and multi pitch tool bars are considered a major break-through in design and application in track press tooling. The interchangeability of tooling between makes and models of tractors results in a substantial cost saving and a reduction of tool inventory. Complete tooling is available for a wide range of tractor makes and models.

Now, 2 kinds of toolings are available from us.

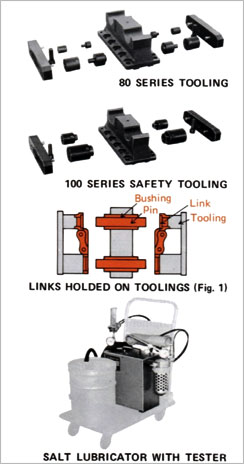

One is conventional type 80 series tooling and the other is newly developed 100 series tooling on which links are holded as shown in Fig. 1.

That is why it is no need to hold them by hand.

You are requested to specify both the tractor models to be served and the kind of tooling when ordering. SALT LUBRICATOR WITH TESTER Check seals in sealed and lubricated track link by vacuum pump and lubricate pin and bush Eall in one set.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact