- ▶Track Rebuilding

- ・Shoe Bolt Torque Controller

- ・Track Shoe Rebuilding Machine

- ・Track Link Welder

- ・Track Press 230 / 330

- ▶Roller and Idler Rebuilding

- ・Roller & Idler Press

- ・Roller And Idler Rebuilding Machine

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Service Car

- ・Lubrication Truck

Workshop Equipment and Tools

Undercarriage Rebuilding

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

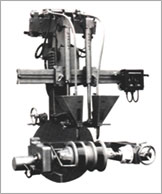

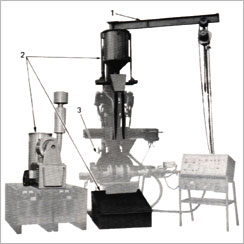

- The MRW-F, with oscillating welding system built-in, allows the rollers and idlers of large-size crawler tractors such as Caterpillar D10 and Komatsu D475 to be rebuilt and it is able to perform either stringer bead welding or oscillation bead welding at the operator’s option.

It is the world’s foremost ideal automatic roller welder.

�E�Shown with optional vacuum flux recovery system. -

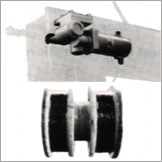

Wire Feeder

The wire feeder handles wire of 2.8 mm to 4 mm (7/64�E�E-1/8�E�E5/32�E�E in diameter at a wide feed rate range of 0 to 2,286 mm per minute. You can choose the most suitable wire size and feed speed according to specific application. [Diameter of welding wire is 3.2 mm (1/8�E�E as standard size]

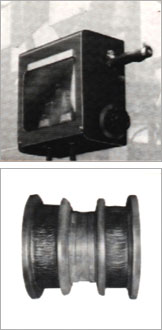

- Welding Head

The welding head has a hopper for supplying flux and a drive motor actuated by a remote control switch to adjust its vertical position (stroke about 500 mm). And also for easy setting and to achieve good welding, a tilting device of forward-backward and right-left hand direction is installed. -

Welding Station

Extra wide welding station is capable of rebuilding even the largest idler with bracket. The welding station can be easily tilted up to 90 degrees counterclockwise and 45 degrees clockwise.

- As the opening of the welding station is very wide, even 2 pieces of the front idlers of idlers can be welded at a time as shown in the above photo. This helps you save time and labor costs considerably.

-

Cooling System

The internal water cooling device developed by Maruma permits crack-free, ideal welding. This process eliminates disassembling and assembling of rollers and idlers and minimizes the parts to be replaced, reducing the cost remarkably. (Patent No.906684).

-

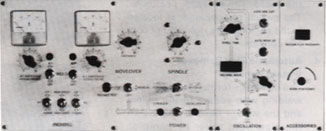

Move-Over System

Automatic move-over system provides stringer welding bead pattern and forms beautiful and even bead. Move-over is automatically done at the range of 1.6 mm to 32 mm. It can be precisely set at any point in the whole range of the carriage beam.

-

Oscillation System

Automatic oscillation welding across the heavily worn tread surface of a roller is very economical. This system eliminates continual slag removal and allows one man to operate 2 or 3 units of welding machines at the same time.

-

Power Unit

The power unit has DC 650A, 100% duty cycle output. The new type of thyristor controls it.

- Pack Turn Table

Pack turn-table is provided which carries pack containing 250 kg of wire or 500 kgs of wire. Wire reel is also available as an option. -

Control Console

The solid-state module operator control console is designed for reliability in any climatic condition. All the switches on the board are arranged in welding order so that even an inexperienced operator can easily operate it. Welding pattern is immediately shifted to stringer bead welding or to oscillation bead welding with the adoption of the newest mode selection system.

-

Water Temperature Control Device

Recently welding specifications have become very severe as new metals are used in rollers. In such case, welding should be done at the temperature specified in order to obtain a good welding effect. The temperature of the internal cooling water can be strictly controlled to meet these requirements. -

Control Console

This Jib crane comes with 1/2 ton electric hoist and 360 degree turn axis for easy loading and unloading of rollers and idlers, also quick unloading of wire packs. We can supply J-hooks for rollers, and lifting tongs for idlers. Mass approx. 185 kg.

Model MVF - Vacuum Flux Recovery System

The MVF automatically recovers excess flux from the bottom flux tray to the hoppers for reuse. During the recycling, the MVF cleans and filters dust from the flux. Mass approx. 250 kg.

ROLLER AND IDLER REBUILDING MACHINE

FEATURES

SPECIFICATIONS

OPTIONAL ATTACHMENTS

�E�Specifications and illustrations are subject to change without notice.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact